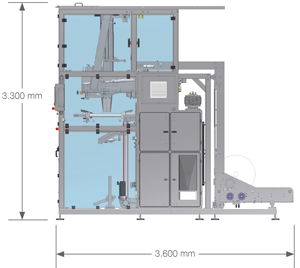

Form Fill and Seal Machine BVC 600

Production of palletizable sacks and bags in a compact and stable format

Dust-free dosing and sack filling

The BVC 600 can pack dusty, powdery products with the highest sealing seam quality. The continuous motion Form Fill and Seal machine BVC 600, produces palletizable bags from the flat film reel. Heat-sealable and weldable mono-materials can be used as packaging material. For dust-free and weight-accurate dosing of powders, a closed filling and auger dosing system is used.

Special feature:

An electric motor can lower the complete format set for cleaning or format changing. Additional lifting equipment is not required.

Highlights

- Dust-free packaging of powders, granulates and pellets

- For large packages in the food and non-food industry

- Executions for powders, granulates, bulk goods, detergents, fertilizers, etc.

- High filling accuracy with volumetric and gravimetric dosing system

- Stable, palletizable sacks by applying a venting valve (valve sack)

- Motor assisted format change

- Bag production from the flat film reel

- Heat-sealable laminates and PE packaging materials possible

- Sack volumes up to 140 liters *

- Sack width up to 750 mm *

- Sealing force up to 8,000 N

* gusseted sacks

The operating principle:

- The product is filled via a controlled feeding auger into the hopper of the auger doser

- With the programmable servo drive, final weights will be achieved with the highest dosing accuracy

- The filled sacks are sealed tightly with the sealing/welding tools of the Form Fill and Seal machine

Advantages:

- The dust-free dosing and filling system ensures for clean and thick seams with a high seam quality

- To achieve a low drop height, the regulated dosing is synchronized with the transport of packaging material

- Weight-accurate dosing through the combination of volumetric and gravimetric dosing process

- High output through the continuous sealing and filling process

- Easy and quick to clean due to clear separation of drive and product area

Venting ensures palletizable sacks (Valve sack)

The operating principle:

- Within the machine, a FDA / BGA permeable valve is generated in the flat film roll

- The valve size can vary according to the ventilation demand

- This valve allows gases and air to escape under stack pressure

Advantages:

- Results in dust-tight sacks with reliable moisture protection