Automated turnkey systems

Customized Solutions

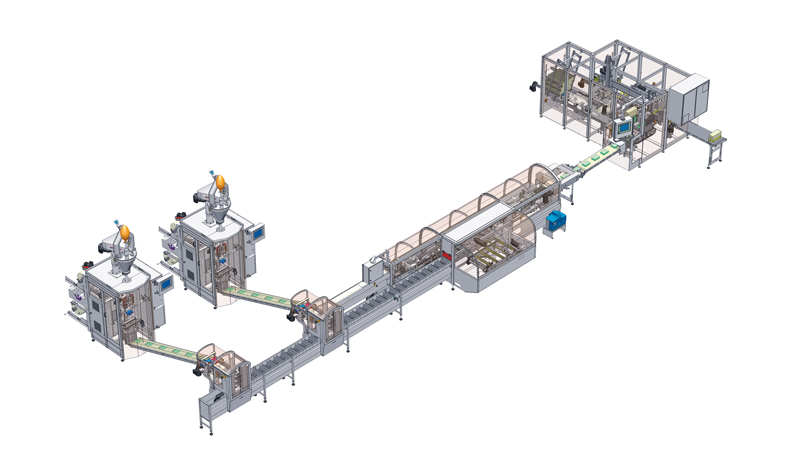

In addition to individual packaging machines, you have the option of combining them to install perfectly synchronised and automated packaging lines or turnkey systems - all from a single source.

While single machines can be installed without extensive planning, complex packaging lines need to meet important requirements on organization, logistics and surroundings. Specialists are needed, guaranteeing the highest user benefit and minimizing the investment risks.

Highlights

- One contact for the entire turnkey project

- Worldwide regional contacts for best maintenance of machine availability

- Simulations and test runs with original product and different packaging materials for various packaging forms in ROVEMA‘s own test and trial center

- High production capacity thanks to coordinated functional units (printers, conveyor belts, drives, etc.)

- High efficiency and maximum availability through use of components from leading system suppliers

- Reliable commissioning, as each system is tested with original product and packaging material at ROVEMA before delivery

- Connection of a customer‘s MES system can be tested together with the customer on ROVEMA‘s premises during commissioning

- Consistent hardware, control and HMI structure

Flexibility that gives you the edge

We integrate customer‘s own systems and aggregates of external suppliers on request. Before delivery, all systems are completely assembled and commissioned and can thus be accepted by our customers with maximum installation safety. Modern machine controls like ROVEMA P@ck-Control or Rockwell allow a complete system synchronization.