26 years of experience in the packaging industry

The important role of automation will become particularly clear. CTO Ingo Hamel reports on how ROVEMA develops innovative, sustainable and efficient packaging solutions.

In today’s fast-paced and fiercely competitive landscape, the packaging industry is undergoing constant transformation. From navigating a shortage of skilled labour to meeting increasingly complex quality demands, companies are facing more challenges than ever before. At ROVEMA, we don’t just understand these obstacles - we’ve made it our mission to help you overcome them. With decades of experience and a deep commitment to innovation, we partner with our customers to turn challenges into opportunities and ambition into achievement.

Production downtimes are avoided during planned machine conversions through advance testing in the ROVEMA Experience Center.

- ROVEMA stands for packaging solutions that are both efficient and innovative.

- ROVEMA ensures the long-term availability of machines, components and spare parts.

- Customers always benefit from high-quality service and have a single point of contact for all matters.

- Production downtimes are avoided during planned machine conversions thanks to advance tests in the ROVEMA Experience Centre.

- This ensures fast changeover times when changing over packaging materials.

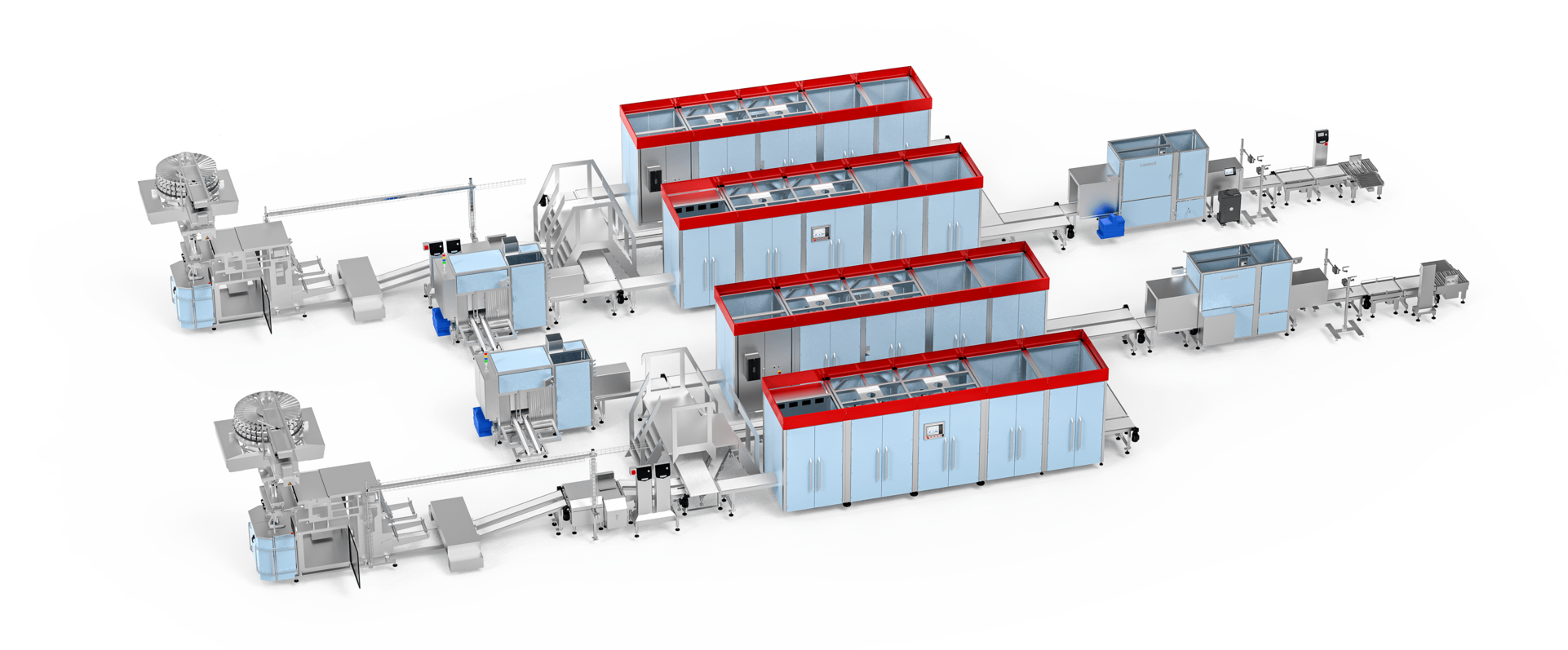

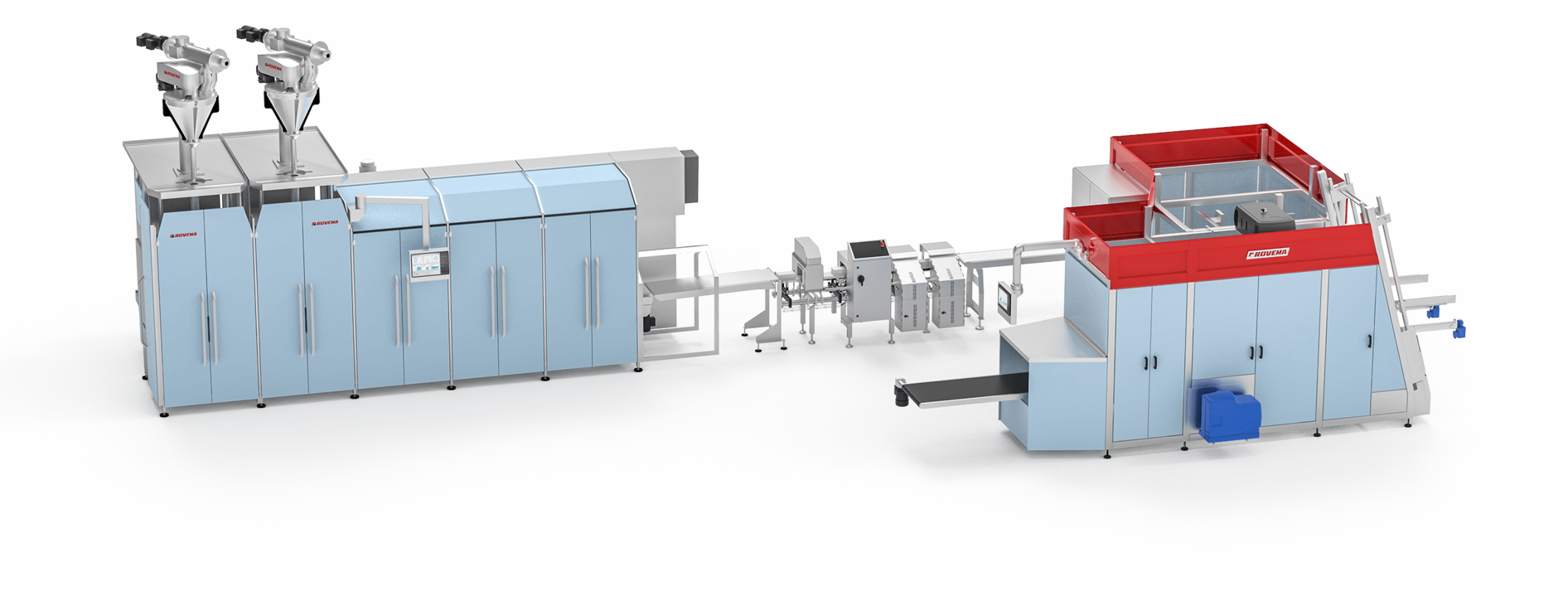

- The machines and systems interlock seamlessly - from product transfer to packaging and palletising.

- ROVEMA packaging solutions are optimised for the packaged goods.

Tradition goes hand in hand with innovation at ROVEMA. "We have been offering customised packaging for over 65 years," says Ingo Hamel proudly. "Indeed, every product has its requirements - be it in terms of the type of packaging or the packaging material. We take on every challenge to offer our customers customised packaging solutions. Automation is playing an increasingly important role here, enabling us to coordinate packaging processes much more efficiently and precisely." explains Ingo Hamel, who can now look back on 26 years of experience in the packaging industry.

Our machines and automated systems enable a fast and flexible response to changing packaging requirements, whether for product presentation in retail or to fulfil protection and safety standards for transport.

Customer service is a top priority at ROVEMA! With us, you have a partner at your side who is always available to provide you with personal and technical advice. ROVEMA is always close to its customers - thanks to an easily accessible service hotline worldwide, personal support, global subsidiaries, sales representatives in more than 50 countries and, last but not least, the ROVEMA Technology Centre. Our Experience Centre at our headquarters in Fernwald offers customers the opportunity to test their specific packaging process requirements without incurring unnecessary expense, retooling or production downtime at their own company. This offers our customers significant added value, as optimised processes lead to more efficient workflows and increased productivity.

“Efficiency is the key factor for the success of any packaging task” emphasises Ingo Hamel.

Efficient packaging solutions: Reducing risks and promoting sustainability

Sustainability is a key issue that affects companies in all sectors. The packaging industry in particular faces challenges here, as packaging is often perceived as harmful to the environment. "ROVEMA can make a decisive contribution to developing and implementing sustainable packaging solutions," says Hamel.

Thanks to innovative materials, our high-quality designed machines are able to optimally process sustainable and recyclable packaging materials. "Companies have the option of using bio-based plastics or recyclable materials that reduce the environmental footprint of their products," adds Hamel. "Our solutions also enable a more precise use of materials, which significantly reduces waste."

The automation of packaging solutions with ROVEMA offers companies the opportunity to make their production processes significantly more efficient and effective.

Every great packaging process starts at the very beginning — with the raw product and its seamless delivery into the machine. At ROVEMA, we know that true efficiency starts with perfect harmony. That’s why we place strong emphasis on the precise synchronisation of all system components, ensuring they work together flawlessly from day one. When machine speeds and processes are fully aligned, production runs smoother, downtime is reduced, and your operations stay on track. But we don’t stop at performance. ROVEMA machines are designed with long-term consistency and flexibility in mind. Whether you’re upgrading a single unit or expanding an entire packaging line, our systems adapt — even years or decades later. Future-ready, modular, and reliable: that’s the ROVEMA promise.

Companies that rely on automated packaging solutions from ROVEMA can make their production processes significantly more efficient and environmentally friendly, as existing resources are optimally utilised. "Material losses are minimised and energy consumption is optimised," explains Hamel. This not only has a positive impact on the cost structure, but also helps to reduce the ecological footprint.

"The result is an automation solution that starts with the receipt of the raw product and extends to the dispatch of the product on the pallet," summarises Hamel.