Modernization of your packaging machine

Due to the global focus on sustainability and responsible resource use, the packaging industry has experienced equivalent pressure to match these initiatives through technical innovations and new packaging ideas.

Companies are currently trying to align themselves to be more sustainable and reimagine their product strategy for rapidly changing markets as a circular economy. A modernization of the machine park with energy-saving, resource-aware processes and the use of sustainable packaging materials present a burden to many of our customers. Together, we are tackling these challenges and can offer you a customized sustainability game plan. Start today – even small steps will help you reach your goal!

Upgrade in a sustainable manner – save energy and raw materials in daily operation

Our sustainable upgrade kits make your machine more flexible and efficient. "Sealing jaws with inserts", "Servo-driven unwind device", "Sliding jaw", "Draw-down belts exchangeable without tools" and "Adjustment unit for film edge control" are all technical developments that can be integrated in many packaging machines with little effort. These small upgrades have major impacts: Raw material savings, reduced wear, reduced energy consumption, optimized packaging material use and process simplification in machine operation are all achievable. In our Newsletter, we will provide you with regular updates on new products at great prices. Reach out to our experienced customer

Extend functions – implement modern, sustainable packaging

Whether you are developing new products, new bag shape or new packaging material. Our machines have always been known for their flexibility. From a simple software expansion to the retrofitting of additional applications – we are there to help and advise you and can provide you with competent guidance through all available options, in order to find the optimum solution for your individual application. Clearly structured checklists simplify communication by clearly determining the key parameters at the start of your project. Technical knowledge, documented machine history and deep technical experience form the foundation of your perfect function upgrade!

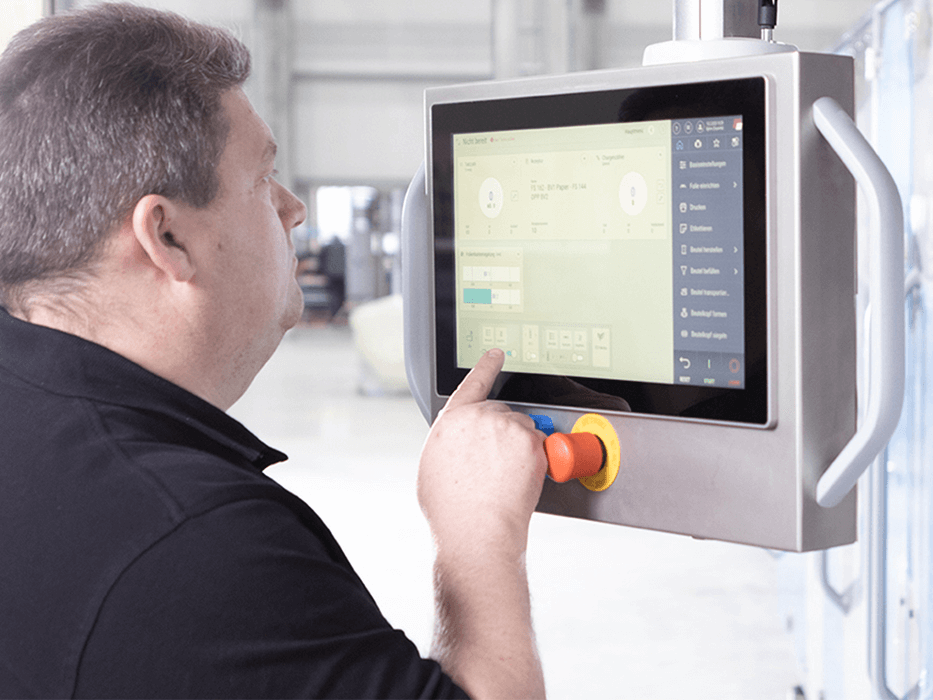

Modernization – at eye level with technical progress

The rapid technical progress that we have experienced in recent years, with digitalization and Industry 4.0, has led to long-lasting technology also being overhauled. Smaller adaptations are no longer sufficient to keep pace with changing technical circumstances, new safety standards and economic conditions. Reconstruction of the machine drives and a complete modernization of the machine control are required.

- A conversion to ROVEMA P@ck-Control extends the lifespan of your machine by maintaining the existing production process and creating the basis for the integration of future technical trends.

- ROVEMA follows a total consultation approach: The decision to modernize your machine is a step towards sustainability! However, the costs for modernization must always be in relation to the purchase of a new machine or a used machine with a general overhaul. We can offer you all three options, and at the end of your consultation, you will have the optimum solution for your individual situation!