Even after decades of usage, we can guarantee the supply of spare parts for many ROVEMA machines. However, a one-to-one exchange is not always the best solution, as electronic components in particular are developing rapidly. This is where risk and opportunity are close together – the risk of no longer being able to obtain obsolete components is offset by the chance to further develop your existing machine and raise it up to a modern control level.

In order to avoid a short-term remedy that is not a permanent solution, it is important to plan such measures in advance to prevent a serious situation. We can offer you a non-binding consultation with a sensibly coordinated upgrade concept for the conversion of your control system to the newest generation of ROVEMA P@ck-Control.

What happens, if single electrical components of the machine break down and are no longer available?

Unplanned machine downtime

Without warning, a faulty electrical component leads to a machine downtime. The necessary spare part has long since become unavailable and even at ROVEMA the stock is exhausted. The elaboration of the requested conversion kit takes time. A new circuit diagram, a new visualization and programming software are required to replace the complete control system. Several weeks will pass from order to delivery and installation on site. The impending loss of production can represent a serious economic loss, but this is avoidable.

Stay flexible with ROVEMA

Prevention can offer you the chance to ensure the long-term availability of your ROVEMA machine: Take your chance to get advice on the advantages of a modern P@ck-Control system – we will be happy to submit you an individual offer!

Together with ROVEMA, you will determine the time for the conversion on site, so you can plan your production in advance to bridge the conversion period!

What does a ROVEMA P@ck-Control conversion involve and what is to be considered?

New, modern HMI display

The operating display is replaced by a new HMI touch display with modern design and menu navigation – probably the most striking change for more efficiency and operating comfort!

ROVEMA Training offers you the possibility to train your personnel in a professional operator seminar, so they will get acquainted with the functions of the HMI display and you will be able to get back into full production after the conversion.

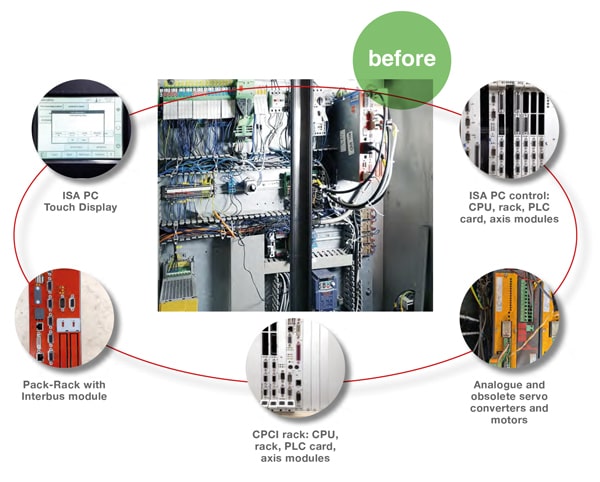

Pivotal point: control cabinet

- The old control system is replaced by a modern industrial PC.

- Servo converters and motors are replaced by devices of the latest generation.

- Replacement of the bus modules by powerful IO modules with expandable connection options.

Safety and support in first place

Digital safety modules are used to upgrade the safety chain to the most state-of-the-art safety standard:

- Pressureless switching of the machine and condition monitoring

- Compliance with national legal requirements

- Improved diagnostics options and monitoring of the safety chain

Über einen LAN/ WLAN-VPN Router können wir Ihnen künftig einen optimalen, elektronischen Remote Service bieten. Die moderne OPC UA Schnittstelle unterstützt die Übermittlung von Produktions- und Maschinendaten an ein Betriebsdatenerfassungssystem – damit stehen Ihrer ROVEMA neue Möglichkeiten im Zeitalter von Industrie 4.0 zur Verfügung!