Our history and important milestones

Driving our own development

Continuous investment in the development of new technologies that form the basis for innovative products and shape the market, and the willingness and ability to embrace change and realign our business to changing customer and market requirements – these things form the basis for our global success and our growth. With energy, creativity and ideas we are able to secure a competitive advantage and jobs. The milestones we have reached are proof of our performance and allow us to look to the future with optimism.

A world first: the first Vertical Form Fill and Seal machine with rotating draw down belts. To date, most of the Form Fill and Seal machines in the world still work in accordance with this technical principle.

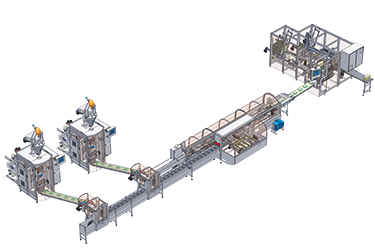

Foundation of the Engineering department for complete packaging lines.

High-speed machine with rotating sealing jaws and continuous film transport.

Development of shelf-ready tray lid packaging.

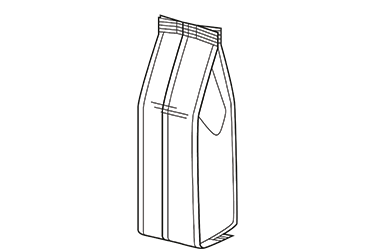

ROVEMA wins the World Star prize for Stabilo Seal. This definitely marks the point where the stable, edge-sealed bag takes over the world market.

SBS Brick pack machine with decentralized drive technology.

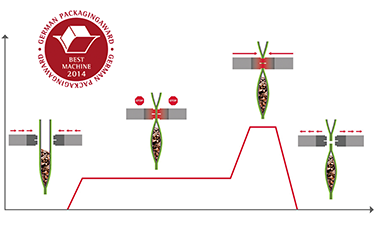

High efficiency and reduction of downtimes due to product detection ROVEMA Sense&Seal.

Introduction of the P@ck-Control machine control system.

Introduction of the ROVEMA VPL.

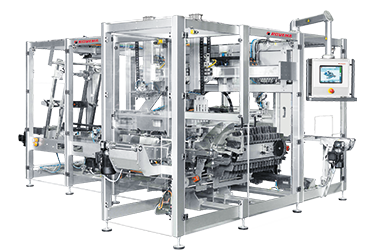

High-performance ETIL Tray Packer for shelf-ready final packaging.

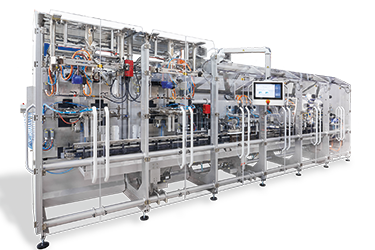

Market launch of SDH for highest hygiene requirements.

Presentation of Stabilo Seal in reel carrier.

Roll-out ROVEMA Second Life Concept.

German Packaging Prize for new BVC Form Fill and Seal machine with Premium Seal technology.

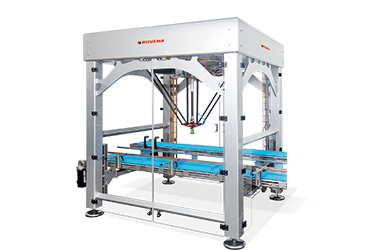

In-house development of an integrated robot control in the upstream VFFS machine.

Introduction of the high-speed machine SBS "Twin".

Successful launch of BVC 260 Flexible for production of all bag styles, including RoPack with re-closure (Zip).

Red Dot Design Award for the new ROVEMA HMI.

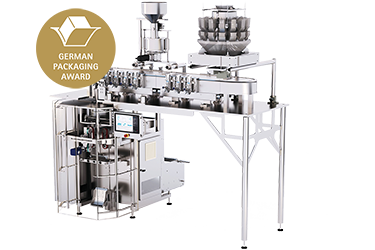

German Packaging Award for ROVEMA Vacuum-Powder Filler (SDH) with SBS Powder Brick Pack machine for low-dust and compact packing of powders and a neat presentation at the point of sale.

Introduction of the high-speed machine BVC 145 Twin-Tube with up to 500 bags/min.

ROVEMA HMI is awarded with the world-renowned iF Design Award discipline „communication“.

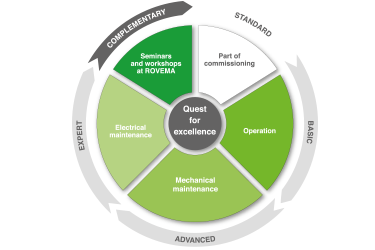

Extension and enlargement of the ROVEMA training offers.

Alignment of ROVEMA company branding with sustainable packaging solutions.

Expansion of the production area in Fernwald by 3,300 m².

ROVEMA acquires DL Packaging, a leading company for retrofit Form Fill and Seal machines.

Acquisition of Hassia India and addition to the international portfolio by adding a strategically important and very solid service and assembly site.

Relaunch of BVC 310 Liquid with a Fitment-Option for usage of pillow bags in dispensers.

ROVEMA becomes active member of the UN Global Compact.

The innovative ROVEMA collect, buffer and feed system CBF wins the German Packaging Award in Gold.

ROVEMA Technical Center: Expansion of systematic packaging material tests in cooperation with leading suppliers. More than 130 tests of sustainable packaging material alternatives in 2020 alone.

ROVEMA takes over inno-tech and Prins Verpakkingstechniek and Engineering and strengthens competence in stainless steel machinery and new applications.

Presentation of the BVC 165 TwinTube as a further development of the 145 series. Especially for the confectionery industry with a larger format range at the same (high) output.

Relaunch of the ROVEMA SBS for fragile products, 35 % increase in output due to empty bag production in continuous mode of operation.

Introduction of the new valve applicator for button valves, 30% performance increase for the coffee industry.

Expansion of packaging solutions made from renewable raw materials, e.g. ROVEMA SUP stand-up pouch made from sealable kraft paper.

Expansion of the industry-specific product range, e.g. for frozen foods, with recyclable paper and plastic solutions.