ROVEMA at Fachpack 2022: Hall 4 / booth 278

Future-proof multi-talent offers fast and reproducible recipe changeover without significant loss of performance.

ROVEMA packaging machines are designed for maximum output and highest flexibility. The established BVC series stands for vertical packaging machines of continuous operation and packs a wide variety of products quickly, efficiently and gently, e.g. in up to 210 flat bags per minute. ROVEMA places a special focus on preparing machines and lines for future packaging tasks. The use of sustainable packaging materials and the production of various bag shapes on only one machine are standard for ROVEMA. Changeover work and set-up times are continuously optimized and also checked with demanding packaging materials. The adaptation of existing machines to new, recyclable packaging materials is usually possible for the ROVEMA BVC series without major performance losses.

With a sealing force of 6000 Newton available in the standard version, the ROVEMA BVC series offers maximum flexibility in the choice of packaging material - recyclable modern mono-packaging materials based on PE or PP or classic composite packaging materials made of PET/ALU/PE can be processed. Packing material changes are quick and easy. The sealing force can be programmed as a parameter and saved as a recipe, making processes reproducible and enabling even small batches to be packaged efficiently.

At the Fachpack trade show in Nuremberg, ROVEMA is exhibiting a BVC 260 specifically for packing coffee - ground coffee, coffee beans, agglomerated or freeze-dried coffee can be processed with gentle product handling and accurate weight. For coffee applications requiring a degassing valve, the machine is equipped with the particularly high-performance new ROVEMA valve applicator for button valves. In combination with a mono-PP packaging material, the BVC 260 thus achieves an output rate of up to 70 bags per minute at a filling weight of 250 g. Packing materials from the flat film web are used, and the aroma valve is fitted in the reel carrier of the packaging machine, offering maximum flexibility at this point as well: the process allows an even wider sealing window, which can be adapted to the requirements of the particular packing material and the button valve selected. Depending on the valve or packaging material, the machine can be equipped with both ultrasonic and heat sealing. This means that an even wider range of packaging materials and valves can be selected, allowing, for example, the packaging to be tailored precisely to the recycling specifications of the market in question. It is also possible to change over to a different valve geometry or a different valve manufacturer with corresponding adaptation of the valve infeed in the course of a format change.

At the Ipack Ima trade fairs in Milan, ROVEMA is presenting a fully recyclable coffee pack with button valve that can also be conveniently retrofitted to existing BVC machines. Both valve and the packing material itself are made of a polypropylene mono-material.

For an output rate of up to 70 packs per minute, Wipf's recyclable WICOVALVE® W109PP disposable degassing valve for bean-to-cup coffee is ultrasonically applied to HATZOPOULOS’ all-PP (89my) high-barrier packaging film designed for recycling, based on the converter’s X-CYCLETM technology. A strong, sustainable partnership.

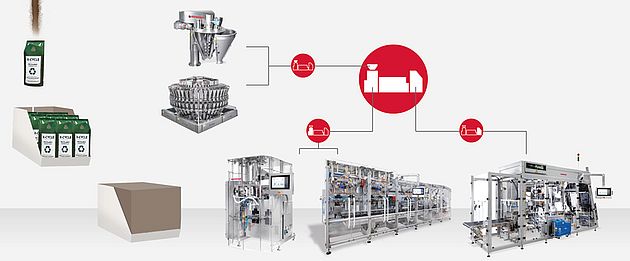

Turnkey solutions for coffee from a single source - from dosing to final packaging suitable for loading or transport optimization.

Learn more about packaging coffee with Rovema

The BVC series offers intuitive, easy-to-understand operation, as well as user guidance with graphic support in the local language. Equipped with ROVEMA P@ck-Control, the BVC also ensures particularly smooth machine operation, which is achieved, for example, by adapting the movement of the sealing tools to the respective bag shape.

A wide range of equipment options allows the machine to be precisely adapted to your individual packaging task, e.g. Rovema offers for the coffee industry:

- Dosing units from own production - for ground coffee, coffee beans, agglomerated or freeze-dried coffee, packaging under protective atmosphere possible

- A dosing system that allows the filling of powder and beans alternately • Integration of multihead weighers from well-known manufacturers

ROVEMA SDH: auger doser, protective gassing possible. Convince yourself of our high-quality auger dosing system live on site in Nuremberg.

- Control valves for recipe-controlled gas quantities • Swiveling sealing tools for easy and ergonomic maintenance and cleaning.

- Servo motorized pre-winding with constant web tension, for a clean and even film run over the forming shoulder

- Ultrasonic edge control for a narrow longitudinal seam that saves packaging material

- Stabilo in the reel carrier

- Various application packages such as automatic reel change (splicer), Stabilo Seal, applicator for reclosure options or labeling systems are also available.

About ROVEMA:

With passion and the experience of more than 60 years, ROVEMA develops and builds packaging machines and lines that meet the complex demands of the modern circular economy. ROVEMA thinks holistically and considers the environment, the market, the product and the packaging in projects from the very beginning. This enables the development of efficient and sustainable packaging machines with high availability. A sustainable solution that fits the characteristics of the product to be packaged and its requirements for logistics, packaging material, shelf life and energy efficiency is ROVEMA's top priority. A successful concept - ROVEMA has already delivered more than 30,000 machines and lines worldwide.

About A. HATZOPOULOS S.A:

A. HATZOPOULOS S.A. develops value-added flexible packaging solutions for the food & beverages, home & personal care, cosmetics and pharmaceuticals industries. Counting more than 90 years of packaging experience, today the company operates on a global level, collaborating with leading brands in over 30 countries. Pioneer in the development of sustainable films, in line with its vision for responsible development, A. HATZOPOULOS S.A. has recently brought to market the next generation of flexible packaging solutions specifically designed for recycling: X-CYCLETM. These novel film formulations aim at delivering both packaging optimization for the Circular Economy and optimum performance, aesthetics and functionality, helping the company’s partners achieve their packaging sustainability goals. Learn more about X-CYCLE: hatzopoulos.gr/x-cycle-recyclable-packaging-films/

About Wipf:

Wipf AG has been developing and producing high-density packaging films and bags for the food, pharmaceutical and non-food industries for more than 100 years. Thanks to Swiss engineering skills and a state-of-the-art production facility, Wipf also supplies disposable degassing valves of excellent quality and functionality for a wide range of demanding applications under the WICOVALVE® brand. In the market for coffee valves, Wipf AG is the quality leader and recognized by major coffee roasters worldwide. The product range also includes sustainable solutions such as monomaterial composites, recyclable PE and PP valves, and certified biologically compostable valves.