The ROVEMA technical centre

Your practical test environment for efficient packaging solutions

In our state-of-the-art ROVEMA technical centre Fernwald, Germany, we offer our customers the opportunity to test their packaging processes under realistic conditions - quickly, safely and without interrupting their own production. This enables you to avoid expensive bad investments or downtimes and optimise your packaging processes.

What is the technical centre?

At the ROVEMA Technical Centre at Ferwald, Germany, you’ll find a wide range of packaging machines and test facilities from different generations. This means you can try out your specific packaging requirements without extra costs, retooling, or downtime in your own production.

“Here we can test on our machines what will later happen in the customer’s production,” explains Dr. Leipold. “With specially designed tests, we discover what truly works, and what doesn’t.” This helps companies optimise their packaging process before moving into full production.

Realistic testing of sustainable packaging

- The requirements for packaging materials are constantly changing, whether due to legal requirements, customer wishes or sustainability goals.

- In the technical centre you can test new, more environmentally friendly materials such as recyclable monomaterials or paper solutions.

- We simulate real-world challenges such as sealing, tearing behaviour, and machine run times, working with you to develop practical alternatives that are both technically reliable and environmentally responsible.

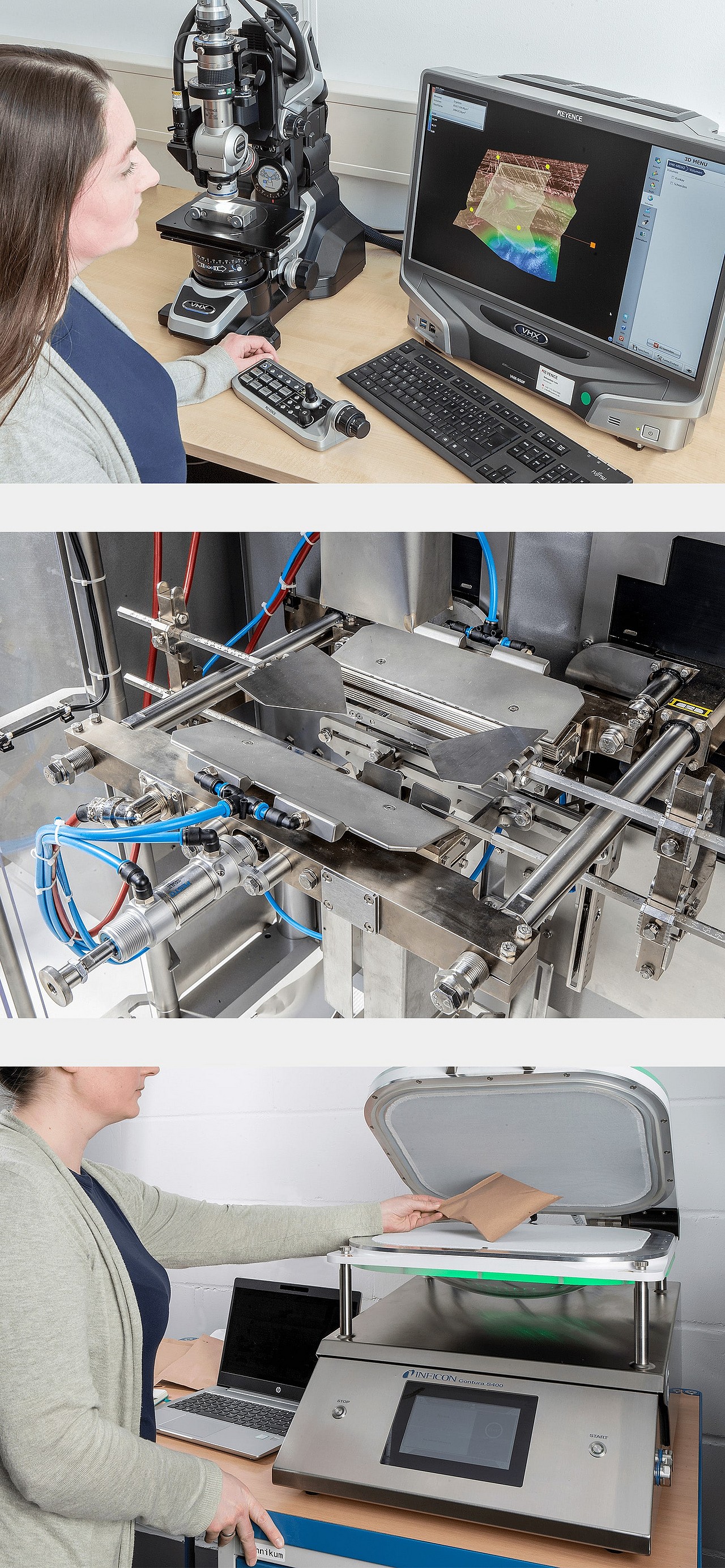

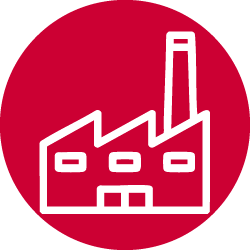

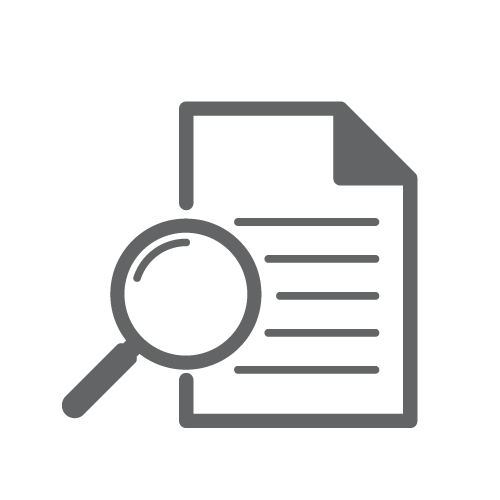

Numerous test procedures are available to you in the technical centre:

- Leak tests on filled and empty bags (water bath, test liquid, Inficon)

- Seam strength and microscope analyses (incl. microtome section) for testing seals

- Filling trials with original products

- Test of different sealing geometries, serrations and longitudinal seam shapes

- Creation of sample bags for presentation or internal approval

- Packaging material analysis before production to identify potential material problems

- Analysis of finished bags to identify defects in seam formation

How to use the technical centre: Your project with ROVEMA

Your request and target definition

You describe the product, requirements and packaging materials. We analyse feasibility and test scope together.

Test runs and material analyses

Carrying out tests with various packaging materials. Tests on seal seam quality, formability, tearing behavior, etc.

Evaluation and recommendation for action

You’ll receive reliable results, such as insights into material processing or optimal machine settings, giving you the support you need when making investment decisions or switching materials.

Process reliability and implementation

Validated parameters for your production. On request: Handover to project planning team or direct implementation with ROVEMA machines.

Maximum safety and cost savings thanks to the ROVEMA technical centre

By combining decades of experience with modern testing methods and realistic conditions, the Technical Centre offers you a double advantage:

- Faster time to market: Validation processes are accelerated by analysing how packaging materials interact with sealing geometry, temperature, and pressure control.

- High reproducibility: Results can be reliably replicated on your own machines under full production conditions, with support from ROVEMA technicians and, if needed, identical components.

- Direct cooperation with packaging material manufacturers: We involve your suppliers in the tests to ensure a harmonious interaction between packaging material and machine.

- Sustainability without risk: Materials such as mono films or paper solutions are thoroughly tested before being incorporated into your production process.

- Tangible cost savings: By avoiding production interruptions, minimising test cycles, and choosing the right materials, you save time, effort, and budget, all while ensuring maximum process reliability.