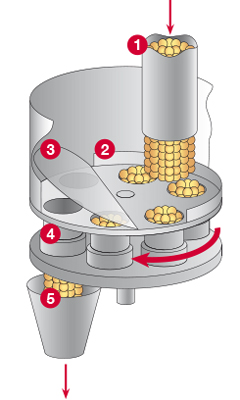

Volumetric cup feeder VDD

Proven technology, high-performing and precise

The proven way of dosing!

It meets the demand of the user within the required legal standards of weight accuracy. The machines may be used as a single unit or in combination with a Form Fill Seal machine. The volumetric cup feeder VDD is designed to dose free-flowing products like pellets or granulates. Within this range a great number of products can be handled as, for example, rice, short-cut pasta, peanuts, pulse, chocolate or sugar.

Benefits and advantages

- Volumetric dosing technology has continuously been optimized throughout decades so that today’s proven components offer a robust and reliable technology that operates almost maintenance and wear free – and – it is simple and quick to clean. This is why the VDD is firmly established in the market.

- ROVEMA’s volumetric dosing system is consequently adapted to the needs of the product, always specifying the construction and the used material for the feed container and dosing cups with regard to the product.

- The different design as a continuous or intermittent operating volume dosing system takes the various requirements of our customers for flexibility into account.

- Working with our customers means a continuous development of our machines in line with production requirements to achieve that out of this experience even most difficult products can be handled trouble-free and within narrow filling tolerances.

- The VDD can be used as a single unit or be combined with other machines as an integral part of ROVEMA system technology.