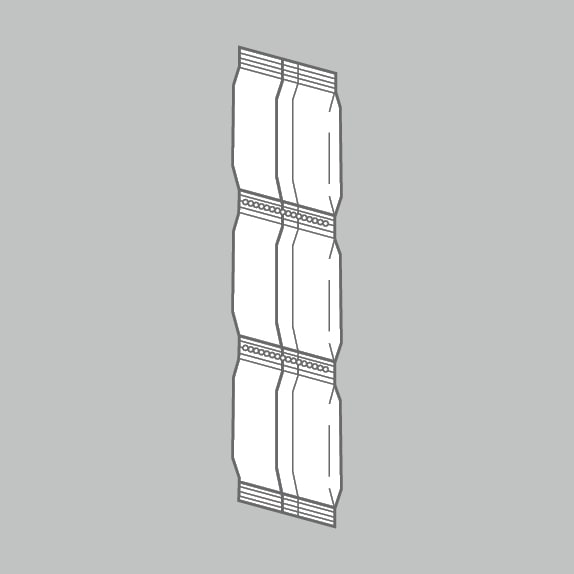

Form Fill and Seal Machine BVC 165 TwinTube

High-Speed packing of sweets and snacks Up to 500 bags per minute!

The continuous motion Form Fill and Seal machine BVC 165 TwinTube offers high efficiency and reduced downtimes due to an independent product detection for both lanes. The bag quality is excellent thanks to the servo-controlled longitudinal sealing. At the same time, the Form Fill and Seal machine impresses with a compact and space-saving design that ensures efficient use of production areas. The low construction height makes it ideal for production facilities with low ceiling heights. With its high output rate, it helps to reduce the cost per bag. In addition, accessibility to all modules and components is ensured, which contributes to an increase in machine availability.

Highlights

- A robust high-performance machine for efficient packaging of loose bulk materials

- Pneumatic film spindle with servo motor pre-film unwinding driven sidewise

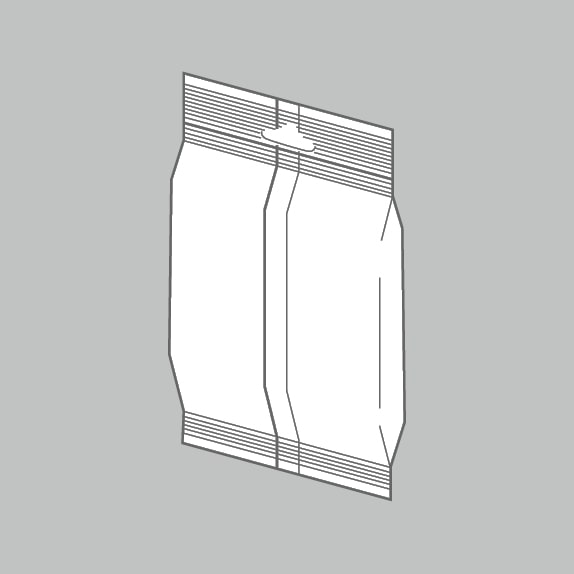

- Packaging material infeed via two single or one common film roll, which is subsequently separated into two film webs

- Integrated control cabinet conveniently accessible from both sides of the reel carrier for cleaning, maintenance and adjustment work

- Automatic edge control for repeatable format change-over and high quality of longitudinal seam

- Electronic product detection for protection of sealing jaws independent for both lines, automatic discharge of defective bags without production downtime

- Best access from all sides since control technology is fully integrated in machine housing (no separate control cabinet)

- Swivelling double protection doors allow optimal access to machine‘s working area

- Wear-free drive technology with servo drives

| BVC 165 TwinTube | |

|---|---|

| Bag width | 50 – 165 mm |

| Bag length | 80 – 220 mm (optional: 320 mm) |

| Nominal output | up to 500 B/min. |

| Sealing force (N) | 6000 N for cross sealing system (independently operated sealing station for both sides) |

Optional

- Infeed of packaging material with two separate film spindles

- Labeler and printer fully integrated into reel carrier

- Verification of BBD (best before date) print through integrated image recognition system

- Product gassing for longer shelf life

- Fully integrated metal recognition system with extractable mounting, integrated before bag production

- Personalized login of operators with RFID reader

- Synchronization with common dosage aggregates, e.g. multihead weighers