ROVEMA at Hispack 2024

Transport-optimized packaging solution for milling products and corn flour: ROVEMA presents their compact packaging line at Hispack 2024

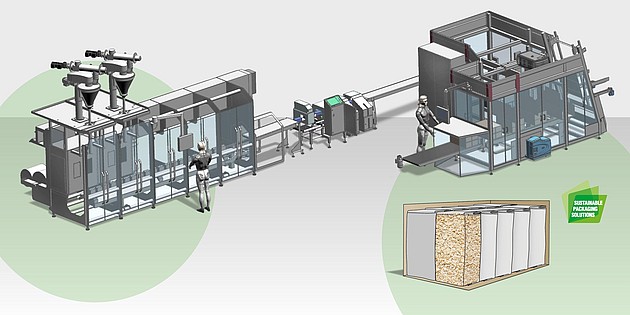

The integrated packaging line from ROVEMA impresses with an output of up to 100 pouches per minute and sets new standards in terms of efficiency and floor space optimization.

The turnkey system on display was specially developed for the transport-optimized packaging of powders, granulates and flakes and offers maximum flexibility in the smallest of space. The upstream block packaging machine from the established SBS series is characterized by its continuous operation and its versatility in bag design.

The new packaging line promises efficient and precise packaging of 1 kg of corn flour with an impressive output of up to 100 bags and 10 WA cartons per minute. The machine has a special dosing system that enables the compression of powders and particularly ensures transport-optimized and low-dust packaging. The high filling level in the pouches and transport cartons maximizes the use of the packaging space.

Particularly noteworthy is the integration of an additional module into the upstream SBS block packaging machine, which will facilitate the processing of sustainable packaging materials in the future. "The SBS Twin from ROVEMA not only offers impressive performance, but also maximum flexibility and efficiency," says Marcell Monleón Lauter, Vice President ROVEMA Spain & Portugal, S.L. "We are proud to present this machine as part of a complete packaging line at this year's Hispack in Spain and to demonstrate our automation expertise to visitors."

ROVEMA has unique line expertise that makes it possible to combine individual packaging machines and install perfectly synchronized and automated packaging lines - all from a single source. This comprehensive line expertise has given ROVEMA's international customers security and a reliable production process for decades.

"When it comes to complex packaging lines, the precise coordination of primary and secondary packaging, a well-thought-out overall layout and an optimized material flow with the best possible accessibility are crucial," explains Ingo Hamel, CTO at ROVEMA. "This calls for experts who can offer the user the greatest possible benefit and minimize investment risks."

ROVEMA plans for you in your existing production facility or for completely new buildings. The advantages of packaging lines from ROVEMA are numerous:

- One contact for the entire packaging line

- Worldwide regional contacts for the best possible maintenance of machine availability and service

- Simulations and test runs with your original product and different packaging materials for various packaging forms in the company's own technical center

- High production capacity thanks to harmonized functional units such as product feed, dosing systems and secondary packaging

- High efficiency and maximum availability thanks to the use of components from leading system suppliers

- Reliable commissioning planning, as every ROVEMA machine and system is tested with your original product and packaging material

- Connection of your MES system can be tested by us during commissioning

- Consistent hardware, control and HMI structure

Visit ROVEMA at Hispack in Spain and see our compact packaging line live in action!

ROVEMA's packaging line is in line with the increasing demands for sustainability and automation in the food and packaging industry. With the aim of being able to react flexibly to packaging material developments and recycling specifications and to offer customers maximum future-proofing and machine availability, ROVEMA is consciously relying on the company's many years of automation expertise.