Form Fill and Seal Machine BVC 310 Fresh

For high hygiene requirements and quick format changes

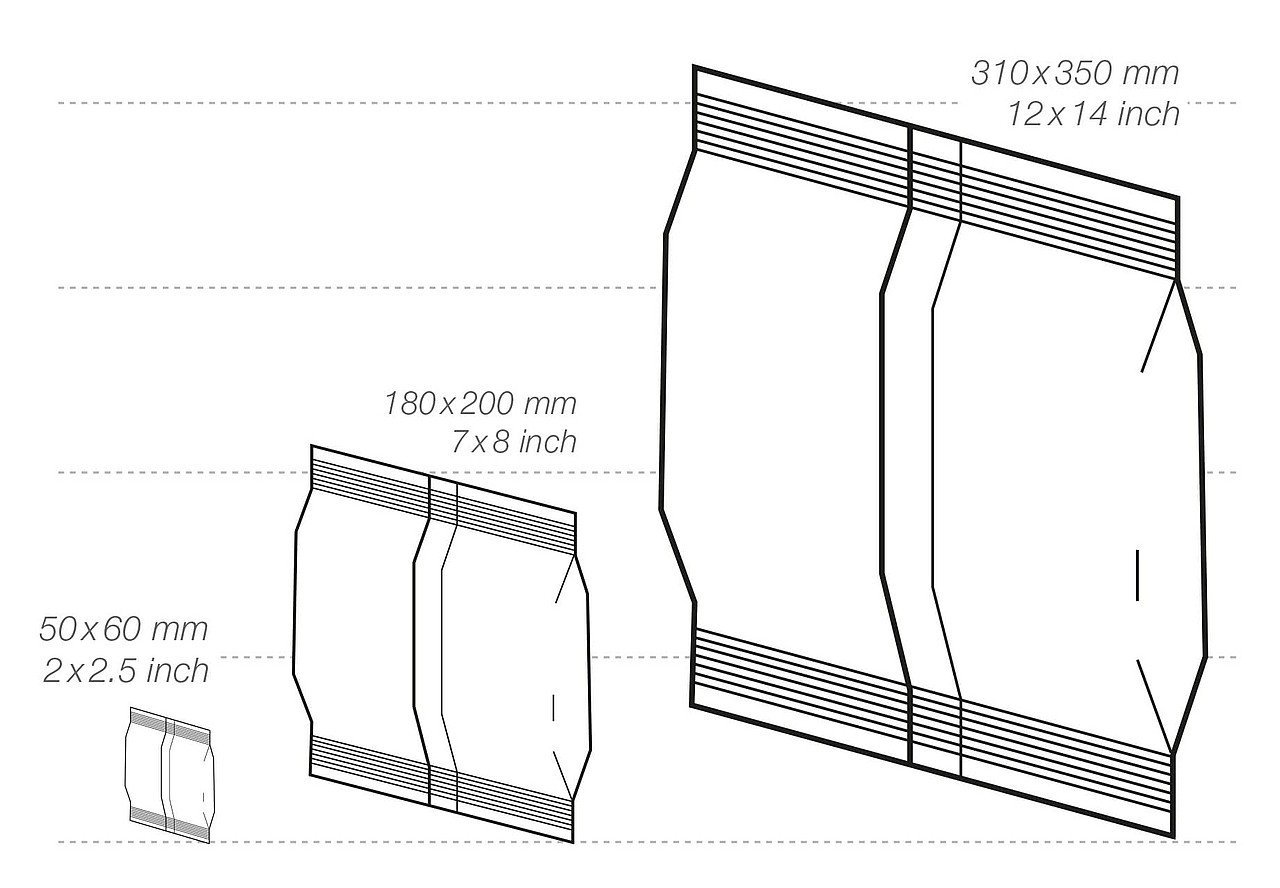

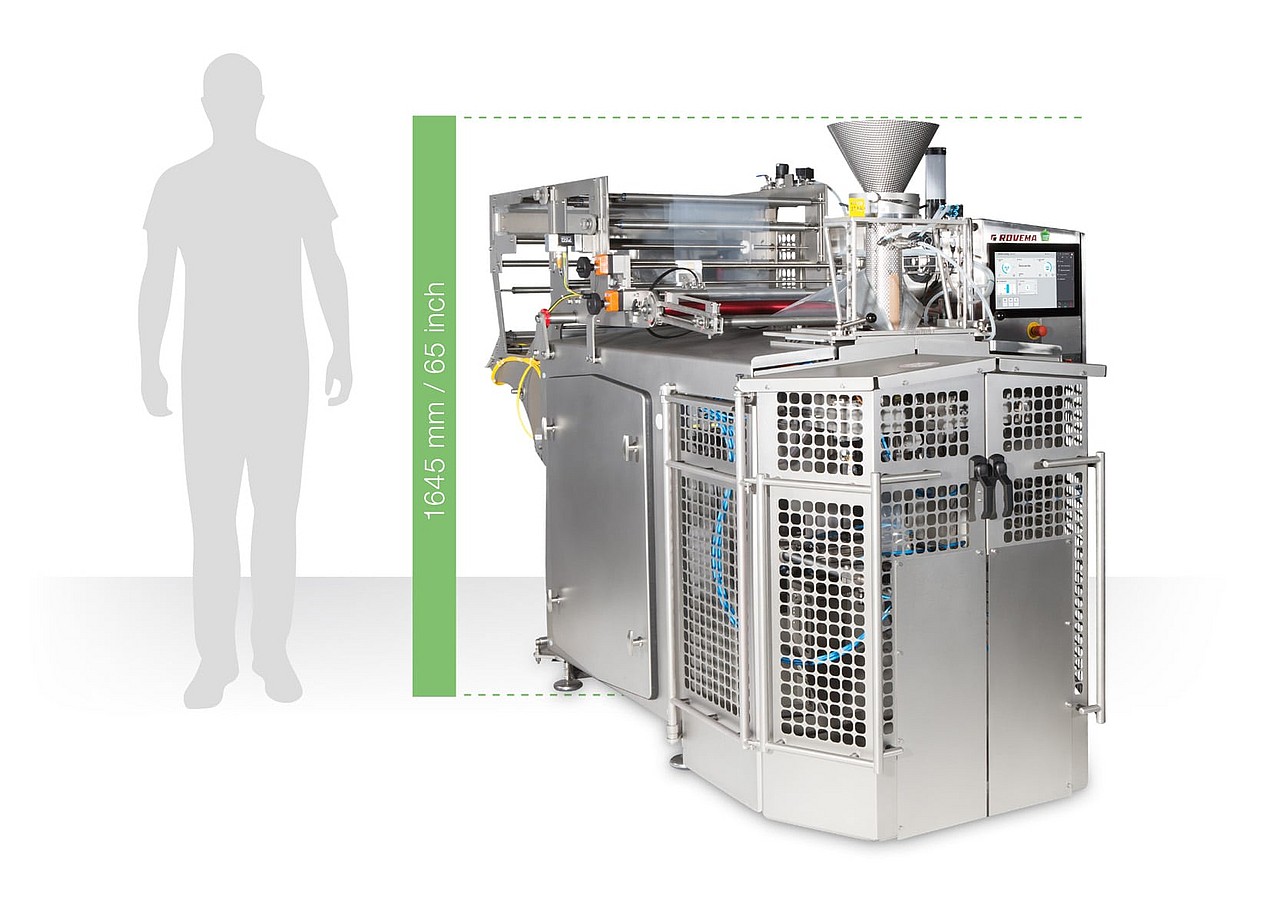

The compact BVC 310 Fresh was specially developed for packaging fresh products such as salad, vegetables and fruit. It enables the packaging process to be optimized in terms of format and product changeover while ensuring first-class bag quality. The machine is ideal for dynamic production environments where time and flexibility are crucial and offers the best possible product protection.

Highlights

- Up to 180 bags per minute

- Compact design with low overall height of 1,645 mm (65 in)

- Wash down version in stainless steel, electrical components in IP 65

- Sealed housing without cavities or flat surfaces

- Good accessibility for cleaning

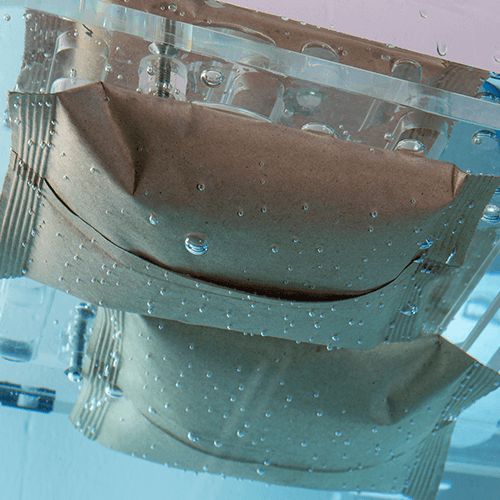

- Optimum bag quality, high product protection for maximum shelf life

Focus on BVC Fresh

Versatility

- Processing of a wide variety of packaging materials possible, e.g. Mono and multilayer packaging materials as well as paper and paper composite packaging materials

- Processing of packaging materials of different thicknesses

- Available with industry-relevant options such as gas flushing, water injection, metal detector, UV-C disinfection, hinged control cabinet, air-conditioned control cabinet and much more.

- The high-speed BVC 310 Fresh is equipped with Sense & Seal product detection and our high-quality sealing technology, Premium Seal.

Ease of operation

- Sophisticated machine design for maximum machine availability

- Wash-down applications; designed without horizontal surfaces

- Prepared for frequent packaging material and product changes, quick and easy cleaning

- With increased hygiene requirements

- Hose station

- Adjustable transition funnel

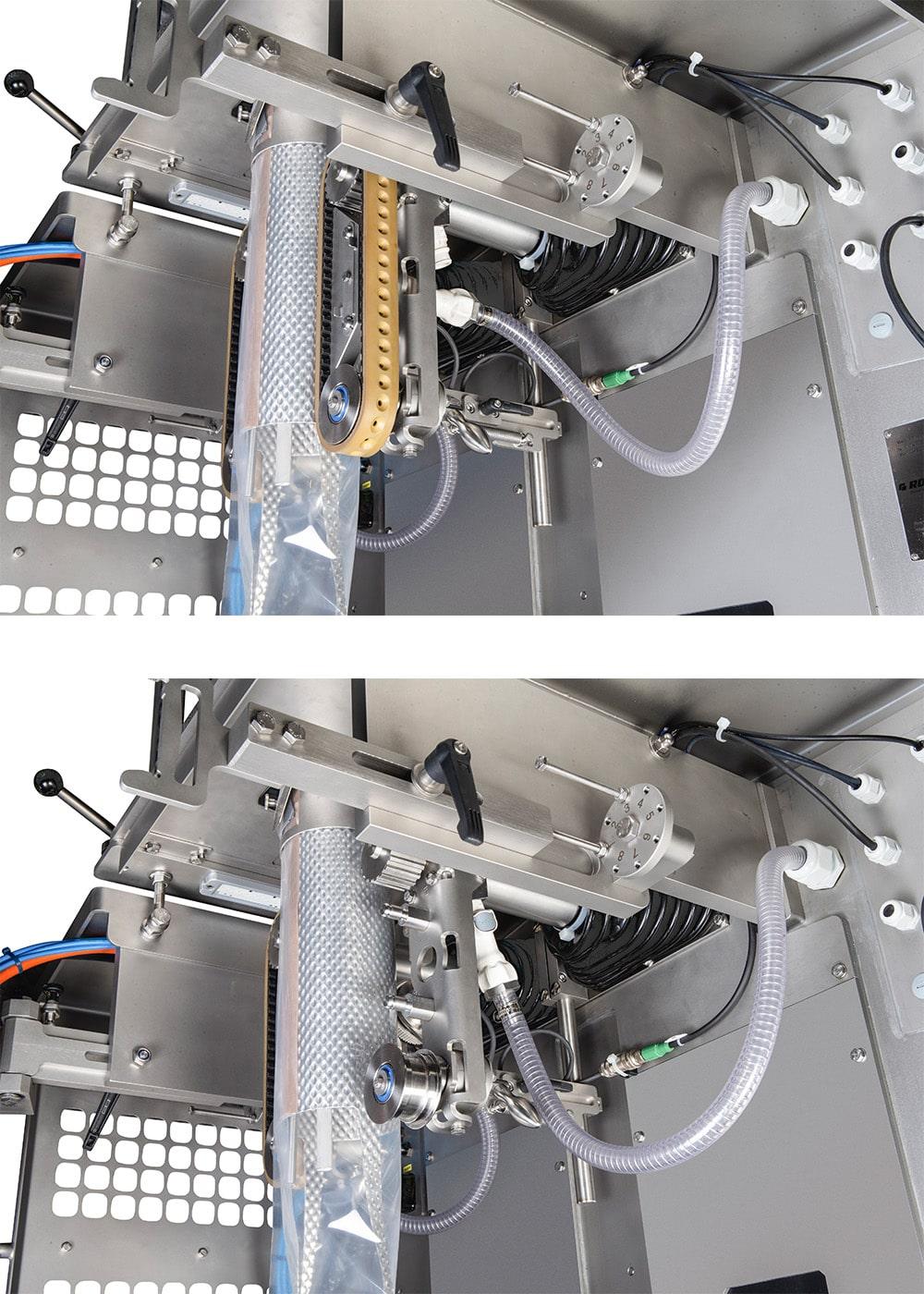

- Filling tube / format tube in special design with textured stainless steel sheet with waffle embossing

- Options to simplify format changes

Ease of use

- Simple, safe operation of the machine

- Optimum accessibility for maintenance and cleaning work

- Multiple swing-open doors

- Highly customizable operator inputs, such as sealing time, sealing force, pouch length and set output via HMI

- User guidance with visual rendering in local language

- ECO mode saves energy during production interruptions

- High pouch quality, quick and easy format changes

Adjustable transition funnel

Easy format changeovers

Hose station

for cleaning

Toolless change parts

for easy changeovers and cleaning

- OPC-UA interface for connection to the customer's control system

- Personalized login via RFID with rights management

- Barcode scanner for simplified recipe selection / packaging material scan

- Format setting via fixed stops, e.g. for rotary preset adjustment

- Interchangeable strips for cross sealing station

- Protective gas flushing

- Water injection

- Metal detector in pull-out carriage

- UV-C sterilization of the packaging material

- Swing-open control cabinet

- Swivel cross-seal jaws

- Air conditioning of machine housing and control cabinet

- Printer and labeler integrated into the film-reel carriage

- Printed content monitoring via eyesight

- Motorized spindle adjustment for printing unit/labeler

- Manual spindle cross adjustment for print mark reader and packaging material edge control

- Manual splice table with cutting and taping for quick film reel change