Bag shape: pillow bag

Packaging material: kraft paper 70 g/m² with partial sealing coat, total 95 µm

Supplier: › Gascogne with Billerrud paper

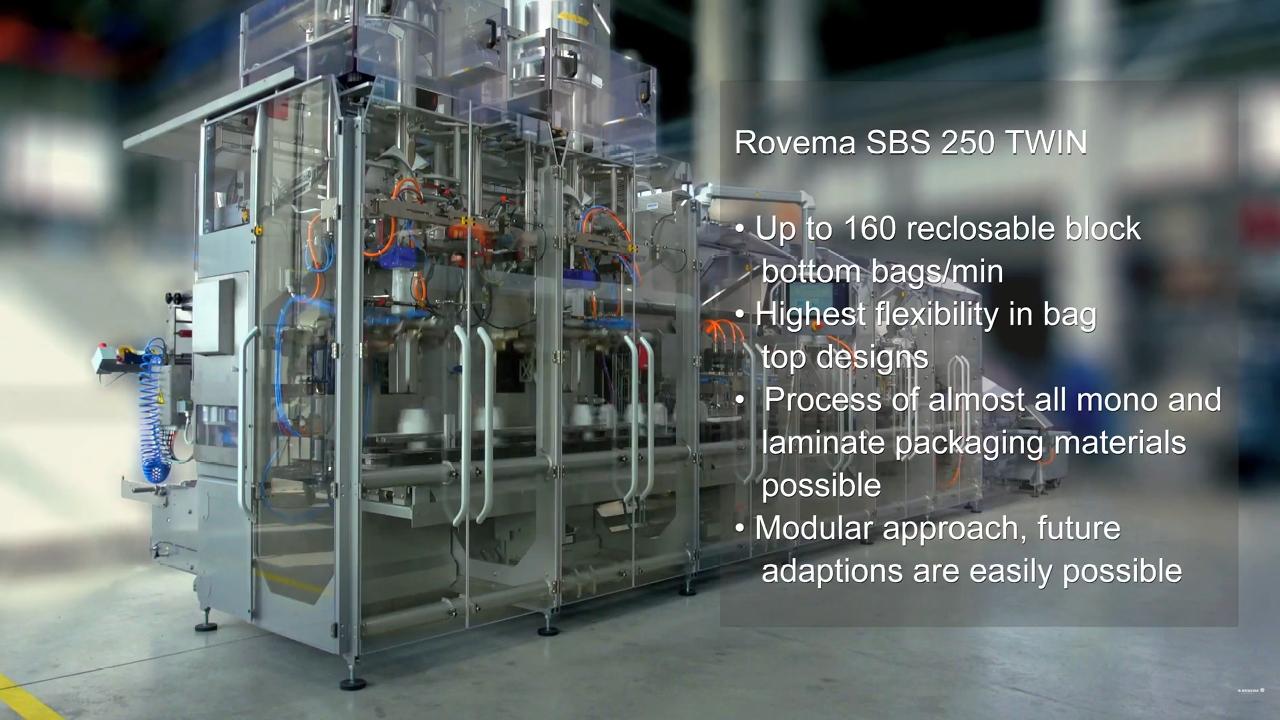

Machine: › BVC 260

No compromises in output performance when processing alternative packaging materials! The tested kraft paper has excellent machinability and is particularly suitable for high-speed pillow bag applications. The high tear and puncture resistance required for packaging short pasta and pulses is taken into account. In addition, this paper packaging material allows the optimum design of the final packaging, since a high degree of filling can be achieved especially when the flat bags are packed horizontally, e.g. in AC cartons: The paper packaging material and also the seam quality withstand a weight from above and the special filter properties of the paper allow excess air to escape from the bag. An even higher proportion of product can be transported.

With a paper content of over 95%, the tested packaging material with partial seal coating can be completely recycled via the paper cycle.