Children's foods are among the most sensitive products in the food sector. Traceability and highest quality standards are part of the industry standard. That is why experience and know-how are required when packing in flexible bags or cartons.

ROVEMA has a distinctive turnkey competence in infant nutrition and offers complete packaging lines from a single source. A turnkey line for baby food powders, consisting of dosing, bagging, spoon feeding, cartoning and final packaging, can thus be quickly and easily converted from bag in box to bag in case mode..

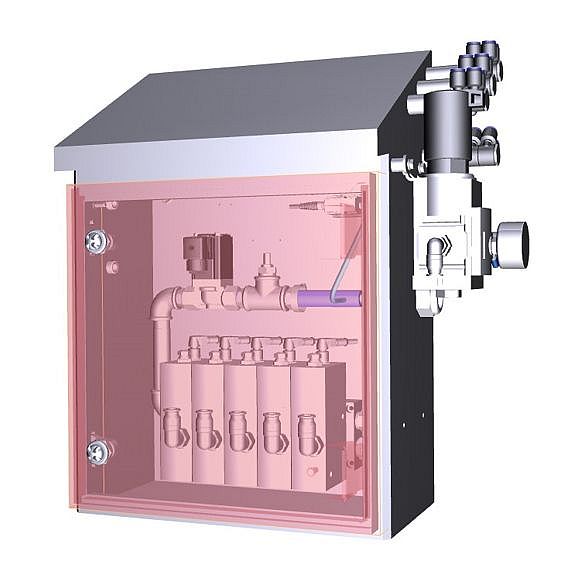

ROVEMA auger fillers SDH allow maximum dosing accuracy with highest product safety and output rate. The product safety monitoring system ACM uses a sound sensor to warn against metallic abrasion in the dosing process and protects against product contamination by smallest particles and dust. Hygienic stainless steel components and a well thought-out design ensure quick and thorough cleaning. The easy machine operation and the tool-free format change guarantee highest efficiency. By providing interfaces such as OPC-UA, ROVEMA prepares the basis for serialization and aggregation in connection with higher-level systems.

A high sealed seam quality, best bag tightness and a comprehensive Life Cycle Service concept complete the offer.